𝗥𝗼𝗮𝗱 𝘁𝗼 𝟯𝟬 𝗸𝗪/𝗸𝗴 𝗼𝗳 𝗣𝗼𝘄𝗲𝗿 𝗗𝗲𝗻𝘀𝗶𝘁𝘆: The Importance of Modal and Harmonic Response Analysis

We are starting a series of technical posts that layout a roadmap of critical aspects of our engineering process that will enable us to reach our goal of designing a motor with a power density of 30 kW/kg.

As we push the boundaries of power density in electric motors, achieving 30 kW/kg requires meticulous attention to every aspect of design and engineering. One critical step in this journey is ensuring the structural integrity and performance of the motor through 𝗠𝗼𝗱𝗮𝗹 𝗮𝗻𝗱 𝗛𝗮𝗿𝗺𝗼𝗻𝗶𝗰 𝗥𝗲𝘀𝗽𝗼𝗻𝘀𝗲 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀.

𝗪𝗵𝘆 𝗶𝘀 𝘁𝗵𝗶𝘀 𝗶𝗺𝗽𝗼𝗿𝘁𝗮𝗻𝘁?

Structural vibrations can directly impact durability, performance, efficiency, and noise levels. Controlling structural natural frequencies is even more critical in axial flux machines. The topology places more mass further from the rotational center, making these motors inherently more unstable than their radial flux counterparts.

Modal and Harmonic Response Analysis

By conducting a Modal Analysis, we identify the natural frequencies of the motor. A subsequent Harmonic Response Analysis allows us to evaluate how the motor responds to operational excitation, ensuring that we avoid resonance conditions that could lead to mechanical failures or degraded performance.

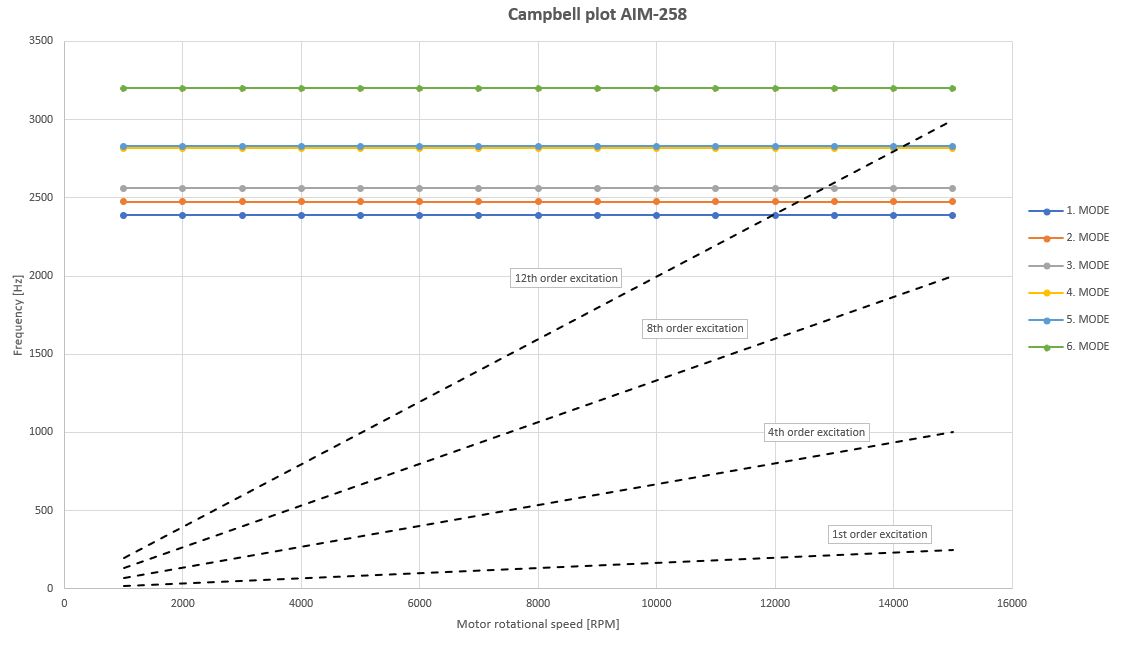

𝗙𝗿𝗲𝗾𝘂𝗲𝗻𝗰𝘆 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀 𝘃𝗶𝗮 𝗖𝗮𝗺𝗽𝗯𝗲𝗹𝗹 𝗣𝗹𝗼𝘁

A Campbell plot is a tool for analyzing vibrations. It helps us identify critical speeds where resonance might occur, leading to potential failures.

- X-Axis: Rotational speed (RPM/Hz)

- Y-Axis: Natural frequencies

- Diagonal Lines: Excitation frequencies (motor orders)

- Horizontal Lines: Natural frequencies of different resonance modes

- Intersections: Highlight resonance risks

By visualizing these interactions, we can adjust designs to avoid harmful vibrations, ensuring smoother and safer machine performance.

Bellow is a Campbell plot for our motor and an example of different modal shapes. We’ve carefully engineered the motor to ensure that its natural frequencies are never intersected during normal operation, ensuring smooth operation.